MSS-SP-55 outlines various defects that can be identified during the visual inspection of castings, particularly those made from cast iron and ductile iron. The standard provides sample photos of the acceptable and non-acceptable defect levels of severity.

The standard if printed on A4 paper is inadequate because the photos are too small and unable to show details of each defect criteria. The photos need to be processed or purchased separately.

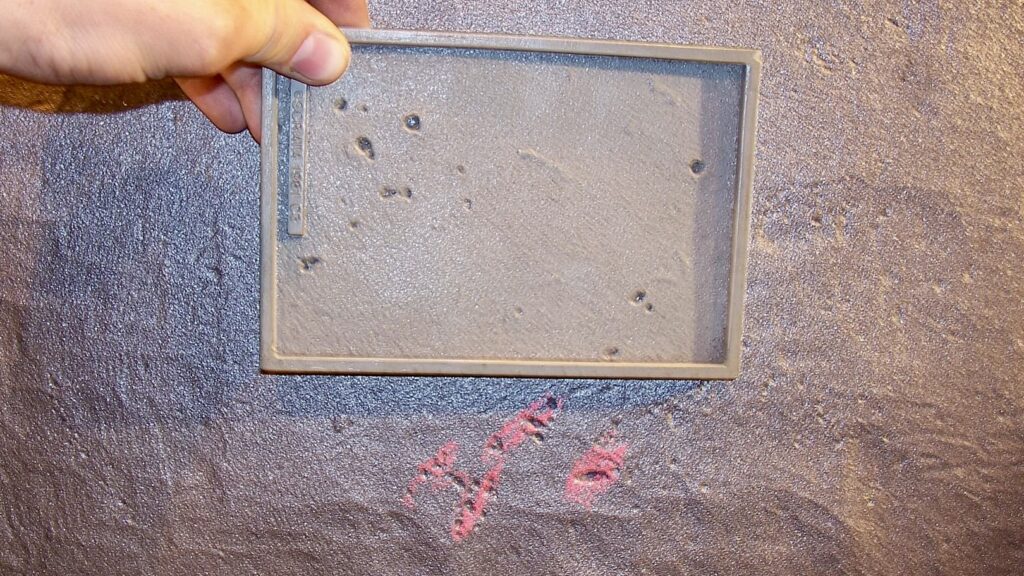

The castings technology institute (CTI) have developed the physical comparator plates for this purpose where inspectors able to quickly evaluate each defect in 3D, visual and tactile (SCRATA Plates) per ASTM A802 and MSS-SP-55

Some of the key defects addressed in MSS-SP-55 include:

Blowholes/Pinholes: Small cavities or holes on the casting surface caused by gas entrapment during the solidification process. The severity is often categorized based on the diameter and depth of these holes.

Cuts: Linear openings or gashes on the casting surface, which may result from molding or core removal processes. The severity is evaluated based on factors such as length, depth, and location.

Metal Penetration: Excessive metal flowing into the sand mold, leading to penetration and fusion with the mold material. This defect’s severity depends on factors like depth and extent of penetration.

Fins: Thin projections of excess metal along the casting’s edges, usually formed due to mold misalignment or inadequate molding techniques. Severity is determined by the length and thickness of the fins.

Mold Shift or Mismatch: Misalignment of mold sections during casting, resulting in an uneven casting surface. Severity is evaluated based on the extent of the mismatch.

Surface Cracks: Cracks on the casting surface, often caused by thermal stresses during cooling. Severity is determined by factors such as length, depth, and location of the cracks.

Hot Tears/Shrinkage Cracks: Cracks formed due to uneven cooling and solidification of the metal. Severity is assessed based on factors like length, depth, and location, and it distinguishes between hot tears and shrinkage cracks.

Inclusions: Non-metallic particles or foreign material embedded in the casting, impacting its integrity. Severity is evaluated based on the size and distribution of the inclusions.

Rat Tails: Thin projections of excess metal extending from the casting surface, often caused by inadequate gating or pouring techniques. Severity is determined by the length and thickness of these projections.

Scabs: Partial separation of the mold material from the casting surface during solidification. Severity is assessed based on factors like size, depth, and extent of scabbing.

Cheers 🥂 MFR