Background History

The oil and whiting method used in the railroad industry in the early 1900s was the first recognized use of the principles of penetrants to detect cracks.

This origin method used an oil solvent for cleaning followed by the application of a whiting or chalk coating, which absorbed oil from the cracks revealing their locations. Soon a dye was added to the liquid.

By the 1940s, the fluorescent or visible dye was added to the oil used to penetrate test objects.

Experience showed that temperature and soak time was important. This started the practice of written instructions to provide standard, uniform results.

The use of written procedures has evolved, giving the ability for design engineers and manufacturers to get the high standard results from any properly trained and certified liquid penetrant testing technician.

Working Theory and Principles

Liquid Penetrant Testing is based upon capillary action,, where low surface tension fluid penetrates into clean and dry surface-breaking discontinuities.

The penetrant may be applied to the test component by dipping, spraying, or brushing. After adequate penetration time has been allowed, the excess penetrant is removed and a developer is applied.

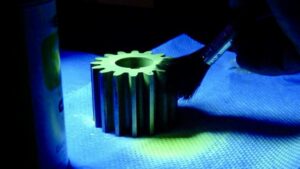

The developer helps to draw penetrant out of the flaw so that an invisible indication becomes visible to the inspector. Inspection is performed under ultraviolet or white light, depending on the type of dye used – florescent or nonfluorescent (visible).

Advantages

• Best test to detect surface cracks or defects in welds

• Cost-effective with fast test results

• Great for materials like metals, plastics, and most ceramics

Disadvantages

• Not suitable for porous materials

• Detects only surface flaws, making surface finish and roughness highly sensitive in testing to avoid masking defects

• Requires training and competency continuity for effective employee certification retention.

Cheers 🥂 MFR

Link to Part 1 : https://firdausrahiman.com/?p=156